SCHOOL OF INSULATION - LESSON 1 - Substrate preparation for insulation

LESSON 1

SUBSTRATE PREPARATION

FOR INSULATIONINSTALLATION

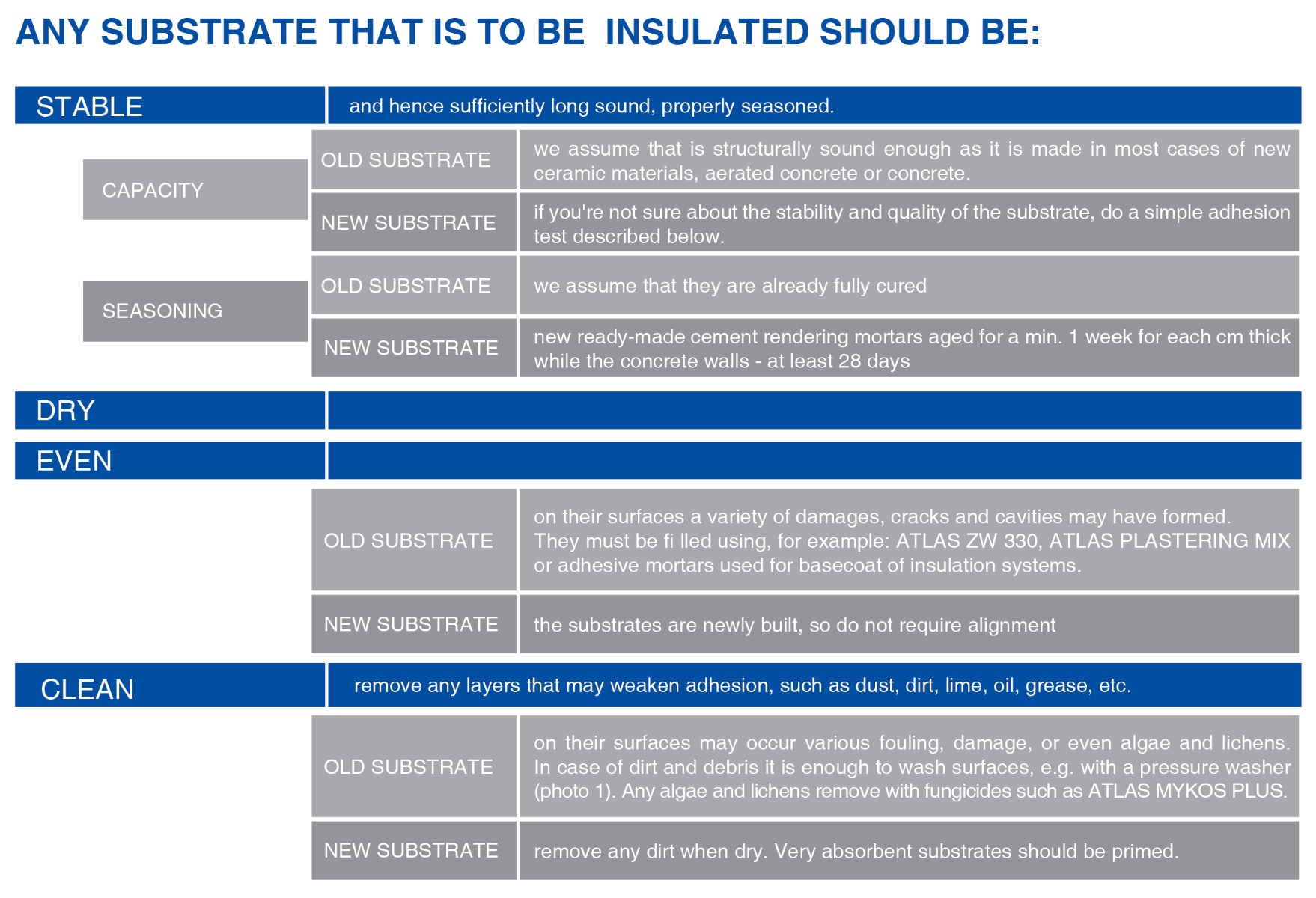

The work starts with checking and preparation of the substrate, to which we attach the polystyrene or mineral wool. There are two types of substrates, on which we can make insulation:

- NEW - new buildings

- OLD - buildings already existing, sometimes with an existing layer of insulation to be modernized.

Careless preparation of the substrate and above all not cleaning of dirt or grease and not removing old coatings, results, in most cases, in disruption of the thermal insulation of the entire wall surface. In the pictures are shown errors and their consequences.

ADHESION TEST

It involves fixing with the use of an adhesive e.g. ATLAS Hoter to the substrate a number of 8 to 10 polystyrene cubes measuring 10x10cm in various places of façade. After 3 days you should try to break the polystyrene cube.

1. If you break off the whole cube with a layer of the substrate, such as render, it will indicate a lack of capacity of that layer. In this case, the entire wall must be examined, and all the weak parts of its surface removed down up to sound section of the substrate. Deleted sections should be replaced with new mortar, for example, ATLAS ZW 330, ATLAS PLASTERING MIX or adhesive used for the insulation. After preparing new substrate, re-check 4 required parameters.

2. If the cube breaks off with all the adhesive and the substrate, such as render, remains intact, it will mean that it is improperly prepared. Or it is too absorbent and requires priming using ATLAS UNI-GRUNT, or it is too smooth, nonabsorbent or coated with non-adherent layers and needs to be cleaned or covered with the - ATLAS CERPLAST/AVAL KT 16. Cleaning can be done using a pressure washer, by washing the surface of the render, next remove the load bearing parts and then reduce its absorption, e.g. by using ATLAS UNI-GRUNT.

3. If the cube tears in polystyrene and one part of it is permanently attached to the wall,

it shows that the surface is stable and suitable for insulation fixing

DICTIONARY:

- U- external wall heat transfer coefficient, calculated according to PN- EN ISO 6946; 2008 (7)

- The EP ratio, calculated in kWh / (m²year), determining the annual computational demand for primary irreversible heating energy, ventilation

and hot water.

IN THE NEXT LESSON:

WE WILL SHOW HOW TO PROPERLY ATTACH THE INSULATING LAYER

Related Products

-

![Acrylic render Atlas SAH N15 dotted white 25kg]() Acrylic render Atlas SAH N15 dotted white 25kg£49.84 / bucket £41.53 / bucket£42.72 / bucket£35.60 / bucket

Acrylic render Atlas SAH N15 dotted white 25kg£49.84 / bucket £41.53 / bucket£42.72 / bucket£35.60 / bucket -

![silicone-render-ATLAS]() Silicone render Atlas SAH N15 dotted white 25kg£71.40 / bucket £59.50 / bucket£61.20 / bucket£51.00 / bucket

Silicone render Atlas SAH N15 dotted white 25kg£71.40 / bucket £59.50 / bucket£61.20 / bucket£51.00 / bucket -

![Fast drying priming emulsion ATLAS UNI-GRUNT 10kg]() Fast drying priming emulsion ATLAS UNI-GRUNT 10kg£24.14 / pack £20.12 / pack£20.70 / pack£17.25 / pack

Fast drying priming emulsion ATLAS UNI-GRUNT 10kg£24.14 / pack £20.12 / pack£20.70 / pack£17.25 / pack -

![Polystyrene facade insulation boards TERMONIUM PLUS EPS 031 50mm/6m2]() Polystyrene facade insulation boards TERMONIUM PLUS EPS 031 50mm/6m2£36.76 / pack £30.63 / pack£31.51 / pack£26.26 / pack

Polystyrene facade insulation boards TERMONIUM PLUS EPS 031 50mm/6m2£36.76 / pack £30.63 / pack£31.51 / pack£26.26 / pack -

![Polystyrene External Wall Insulation sheets TERMONIUM PLUS EPS 031 80mm/3.5m2]() Polystyrene External Wall Insulation sheets TERMONIUM PLUS EPS 031 80mm/3.5m2£34.30 / pack £28.58 / pack£29.40 / pack£24.50 / pack

Polystyrene External Wall Insulation sheets TERMONIUM PLUS EPS 031 80mm/3.5m2£34.30 / pack £28.58 / pack£29.40 / pack£24.50 / pack -

![Polystyrene External Wall Insulation sheets TERMONIUM PLUS facade EPS 031 pack 100mm/3m2]() Polystyrene External Wall Insulation sheets TERMONIUM PLUS facade EPS 031 pack 100mm/3m2£36.76 / pack £30.63 / pack£31.51 / pack£26.26 / pack

Polystyrene External Wall Insulation sheets TERMONIUM PLUS facade EPS 031 pack 100mm/3m2£36.76 / pack £30.63 / pack£31.51 / pack£26.26 / pack -

![Polystyrene graphite boards TERMONIUM PLUS 031 30mm [m2]]() Polystyrene graphite boards TERMONIUM PLUS 031 30mm [m2]£3.68 / m2 £3.07 / m2£3.16 / m2£2.63 / m2

Polystyrene graphite boards TERMONIUM PLUS 031 30mm [m2]£3.68 / m2 £3.07 / m2£3.16 / m2£2.63 / m2 -

![Polystyrene graphite insulation boards TERMONIUM PLUS 031 20mm [m2]]() Polystyrene graphite insulation boards TERMONIUM PLUS 031 20mm [m2]£2.45 / m2 £2.04 / m2£2.10 / m2£1.75 / m2

Polystyrene graphite insulation boards TERMONIUM PLUS 031 20mm [m2]£2.45 / m2 £2.04 / m2£2.10 / m2£1.75 / m2

Search for content

Post categories

![Polystyrene graphite boards TERMONIUM PLUS 031 30mm [m2]](https://www.ibb.uk/media/catalog/product/cache/f7625e340e2d67ce341a8011f0105729/s/t/styropian-grafitowy-termo-organika-termonium-plus-fasada-031-30mm-m2-13681-1-en.jpg)

![Polystyrene graphite insulation boards TERMONIUM PLUS 031 20mm [m2]](https://www.ibb.uk/media/catalog/product/cache/f7625e340e2d67ce341a8011f0105729/s/t/styropian-grafitowy-termonium-plus-fasada-031-20mm-m2-13677-1-en.jpg)